by Jeffrey

Herman

(click on photos to enlarge image)

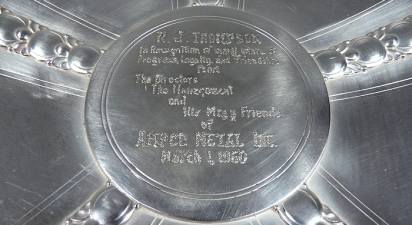

BEFORE AND AFTER ON A TIFFANY STERLING PLATE

This plate came to me with chased lettering

(not engraved) that the customer wanted removed

and the overall look brought back to its

original beauty.

I couldn't planish out the lettering because the

metal would dramatically deform and loose

thickness.

I couldn't fill it in with silver solder because

of all the pin holes and color difference that

would result. And electroforming wouldn't do.

This job required the use of my pulse arc welder

and was going to very complex.

The lower parts of the lettering were very thin

as it was chased on a steel form, and the

slightly rounded corners would be more difficult

to level with the overall disk.

These factors required numerous setting

adjustments on the welder.

|

|

On the right I'm flattening the over-filled

sterling mounds with a special smoothing mode.

This entire filling and smoothing process was

extremely time-consuming, requiring enormous

concentration and constant refocusing of the 10x

microscope.

|

|

The lettering completely filled

|

|

The center disk shows no sign of

ever having been chased

|

The deposited sterling was then planished

over a slightly domed stake to remove any

porosity left by the welding. Then, 600-, 1200-,

and 2000-grit silicon carbide wet/dry paper was

used to remove any high spots and prepare the

surface for polishing.

|

| . |

The plate was repatinated and lightly polished,

resulting in a

dramatic transformation. The entire restoration

took over 14 hours!

|

. |

Jeffrey Herman

- 2012 -

|

Jeffrey Herman worked at Gorham as designer,

sample maker, and technical illustrator. Upon

leaving Gorham, he took a position at Pilz Ltd where

he learned the fine art of restoration, and

fabricated mass-produced ecclesiastical ware. He

earned a BFA degree in silversmithing and jewelry

making from Maine College of Art in Portland,

studying under Harold Schremmer and Ernest Thompson,

two outstanding designer/craftsmen. He started his

business in 1984 gaining a national reputation of

quality craftsmanship repairing and reconstructing

everyting, from historical pieces to single spoons.

He is the founder of the Society of American

Silversmiths.

Further details about Jeffrey Herman and information

contact are available in his website at

http://www.hermansilver.com

|

|

|