by Jeffrey

Herman

(click on photos to enlarge image)

BEFORE AND AFTER

I have repaired and reconstructed everything,

from historically important tankards, tea

services and tureens to disposal-damaged and

dishwasher-dulled flatware.

Illustrated are some of the objects I have restored.

This is a large Gorham soup tureen with caved-in

base, dented body and cover.

The piece was in a fire and the soot was fused

to its surface - not a pretty sight...

|

|

|

The base dents are burnished out. The

process moves from the outside of the base to

the inside, using highly polished steel tools in

various shapes, minimizing any change in the

surface of the tureen.

Since this piece was created in the 19th century,

it's very important to retain the small

scratches and dimples that have accumulated over

the decades...

|

Burnishing out the body dents.

Whenever possible, burnishing is preferable than

hammering because the metal stretches very

little and produces no hammer marks...

|

|

|

The burnishing continues - from the outside

of the piece to the inside-back and forth as

many times as it takes to make surface as smooth

as glass.

This process requires a tremendous amount of

pressure to force the dent back to where it's

level with the surface around it...

|

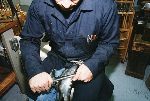

The body dents are removed with heads that

conform to the compound curve that's being

burnished out.

The head is placed in a horse - a long steel

receptacle which is in turn placed in a heavy

vise...

|

|

|

Sometimes a highly polished planishing

hammer must be used to force down pinpoint dents

that cannot be removed with burnishers. Rubber,

wooden, or plastic hammers are considered before

resorting to the steel hammer which will remove

the toughest dents, leaving shallow marks that

must be burnished out, filed, and/or buffed ...

|

A wooden hammer is used to remove the edge

dents on the cover, making sure every hammer

blow strikes squarely without distorting the

metal.

A highly polished t-stake is used to back-up the

cover and absorb the blows...

|

|

|

The finished piece after 5½ hours of work!

Notice that the monogram on the body remained

intact.

The entire piece was hand finished to look as it

would have before its battering.

The tureen sits atop a surface plate which was

used in conjunction with a height gauge to

insure that the piece is now level.

|

This cruet stand arrived in my shop with one

foot missing. An existing foot was removed,

duplicated with electroforming, and reattached along

with the new foot.

Dents were removed, and even patina was applied,

and the piece was hand finished.

|

|

|

This baby cup was actually run over by a

truck in the 1920s. The handle had to first be

removed and reformed. The cup had to be annealed

numerous times to soften the metal, allowing for

the creases to be opened and the body to be

reformed. The imperfections along the hollow top

edge could not be corrected because the metal

was very thin. Any tool used to repair the edge

would result in a poor result, or worse -

tearing the metal! Notice that the engraving on

the right side of the body was preserved. The

90-year-old owner gave the cup to his

granddaughter on her first Christmas.

|

Jeffrey Herman

- 2011 -

|

Jeffrey Herman worked at Gorham as designer,

sample maker, and technical illustrator. Upon

leaving Gorham, he took a position at Pilz Ltd where

he learned the fine art of restoration, and

fabricated mass-produced ecclesiastical ware. He

earned a BFA degree in silversmithing and jewelry

making from Maine College of Art in Portland,

studying under Harold Schremmer and Ernest Thompson,

two outstanding designer/craftsmen. He started his

business in 1984 gaining a national reputation of

quality craftsmanship repairing and reconstructing

everyting, from historical pieces to single spoons.

He is the founder of the Society of American

Silversmiths.

Further details about Jeffrey Herman and information

contact are available in his website at

http://www.hermansilver.com

|

|

|